When it comes to waterline treatment, ignorance is no excuse. : By Laura Thill

Despite the growing awareness around the importance of waterline treatment, some dental practices still don’t adhere to testing protocols to protect the dental team and their patients. Either they aren’t making the effort or they’re going about it all wrong, according to Air Techniques Inc. dental hygiene specialists Gaylene Baker and Carly Fish.

“It has been my experience that dental practices rarely get waterline treatment correct,” says Baker. “Either they don’t understand that something needs to be done, or they are utilizing a product completely incorrectly. Each product that is used to treat dental unit waterlines (DUWLs) has a specific protocol that should be followed to prevent biofilm growth and maintain units of heterotrophic bacteria per milliliter of water (CFU/mL) at or below 500 CFU/mL. Simply complying with a portion of a waterline treatment’s IFUs isn’t sufficient and can put patients and clinicians at risk of being exposed to disease causing microorganisms.

“In my experience, some dental offices are not doing as good a job as they can of maintaining and monitoring the dental waterlines,” says Fish, noting that some dental offices only test their dental water when an incident prompts them to do so. “Many clinical teams forget to maintain waterlines and are unaware of how to properly maintain the dental water quality, she points out. “If the practice doesn’t treat their waterlines, the microbial count can reach as high as 200,000 CFU/mL in a matter of days, even when the tubing lines are new. I’ve had dental assistants and hygienists discreetly tell me the water smells or tastes funny, which obviously is not a good sign.”

Fish recommends that dental practices take the following steps to ensure their waterlines meet acceptable standards:

- Test. Test water on a regular basis (ideally every three months) and monitor the water quality to ensure bacterial counts remain at 500 CFU/mL or less.

- Shock. If the dental practice suspects the waterlines are compromised and the microbial counts have exceeded 500 CFU/mL, it should initiate treatment immediately.

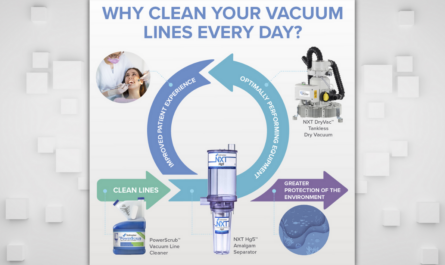

- Maintain. The practice should follow manufacturer guidelines for disinfecting waterlines and eliminate dead ends in plumbing, where stagnant water can enable the formation of biofilm.

- Daily drain and flush. Per recommendations by the Centers for Disease Control and Prevention (CDC), the American Dental Association (ADA) and the Organization for Safety, Asepsis and Prevention (OSAP), dental practices should flush their waterlines for several minutes each morning, before they begin patient visits. They should flush handpieces with air/water for 20-30 seconds between patient visits. And they should install sterilized handpieces and sterile or disposable syringe tips after flushing to reduce cross-contamination.

“Using an independent water reservoir system will eliminate the inflow of municipal water into the dental unit,” she adds. “This will permit better control over the quality of the water source, and eliminate interruptions in dental care when ‘boil water’ notices are issued by local health authorities.”

Misconceptions

If some dental practices are lagging behind with regard to waterline treatment, it’s certainly not intentional in every case, note Fish and Baker. “Some dental practices may think that because they’re using distilled water, they are supplying safe water to their patients,” says Fish. “They may not realize that biofilm is growing within the water lines.”

Waterlines are moist, warm and dark, with periods of stagnation and slow flow rate, making them breeding grounds for biofilm, she points out.

It’s not uncommon for dental practices to believe their treatment protocol is simpler than it really is, leading them to overlook important steps, says Baker. Furthermore, they may not realize they need to validate that they are complying with EPA and CDC treatment standards to ensure their water does not exceed 500 CFU/mL, she explains. Even if a product does not include validation recommendations in the IFUs, the practice must take necessary steps to validate their protocols and account for the possibility of errors occurring. “Dental offices often have a waterline design that facilitates growth of biofilm that can be released into treated water causing a CFU count over 500/mL,” she says. “If they don’t monitor their waterlines, how will they know this?

“There is also a great misunderstanding that utilizing distilled water is sufficient, and no treatment is required,” she continues. “Distilled water is a great source of water, but without waterline treatment, the DUWLs will absolutely grow biofilm.”

Misunderstanding or not, when dental professionals are negligent, they place both their patients and their practice at risk. Take an incident impacting a Georgia pediatric dental clinic in 2015, where 20 children who received pulpotomies required hospitalization due to chronic infections. “The investigation revealed a direct link between these infections and contaminated dental unit water at the clinic,” says Fish. “The average CFU count was 91,333/mL,” she explains. “M. abscessus was isolated from all water samples and genotyping validated that it was responsible for introducing infections into the chamber of the tooth during irrigation and drilling.” Signs and symptoms of this infection include pain, swelling, osteomyelitis (an infection of the bone), pulmonary nodules (a small, round- or oval-shaped growth in the lung caused by an infection) and fever. Treatment can be extensive and expensive.

“The bottom line is, if the dental office is negligent and doesn’t treat its waterlines, there are legal implications,” says Baker. “I didn’t know is not a defense. It is every dental practice owner’s duty to know what must be done in order to comply with laws or guidelines. They also have to train their employees on why waterlines must be treated, and how to treat them. And, they must implement an office policy specifying how the dental team should use their chosen product and validate compliance.”

The good news is that, while some dental practices have some catching up to do with regard to waterline treatment, market data reflects a growing interest in newer products available to ensure dental water meets EPA drinking water standards, according to Fish. “Given how much this product category has grown in recent years, it’s clear that more and more dental offices recognize the importance of treating their waterlines,” she says.

Today, in-office and chairside water test kits are available, which are convenient, economical and save doctors time, Fish points out. “Although less reliable than laboratory testing, in-office tests provide actionable results based on a pass/fail baseline, enabling the dental office to take fast action if biofilm starts to gain ground.

In-office tests require a sample be taken directly from each unit and left to incubate for 2-5 days, depending on the method used,” Fish continues. If used more frequently, these tests can help ensure staff compliance and provide an early warning if there’s a problem, she adds.

“Air Techniques offers Monarch Lines Cleaner, an intermittent, chlorhexidine-based liquid treatment,” Fish explains. “Monarch Lines Cleaner is both a shock and maintenance product. It removes biofilm containing odor-causing bacteria from dental unit waterlines with a fast, effective and efficient application. The solution is ready to use, with no mixing or diluting required. After coating the tubing walls nightly for 3 weeks to ensure buildup in waterlines is eliminated, Monarch Lines Cleaner should be used weekly.”

Clear and concise

As important it is for dental professionals to follow manufacturer instructions for use, it’s up to manufacturers to provide clear, concise instructions, notes Baker. IFUs for waterline treatment products can be confusing to say the least,” she says. “Is it necessary to shock? If so, when? Do I need to test? Again, when?” Whole office systems require maintenance with shocking and filter changes, she adds – something dental offices may not realize. “Many dental offices believe that once they install whole office systems, they are finished, but that’s not true,” she points out. Manufacturers bear the responsibility of providing easy-to-follow documents, which may also be used for recordkeeping to keep track of treatment, monitoring and protocols for addressing failed tests. “This would help dental practices follow proper protocols for their product of choice, and keep clinicians and patients safer in the long run,” she says.

It’s especially important that dental professionals understand the risks involved if they do not follow the product IFUs and adhere to CDC guidelines, notes Fish. “Easy-to-follow instructions and instructional videos can be helpful,” she says. “In addition, manufacturers should follow up with the office once the sale has been made to ensure the customer is using the product according the to the IFUs.”

Running a dental practice can be overwhelming, says Baker. Add to that the need for regular waterline filter changes, shocking, monitoring and recordkeeping, she points out. The better educated dental professionals are with regard to the importance of adhering to waterline treatment protocols and maintaining EGP drinking water standards, the better equipped they will be to keep their staff and patients safe.