By Sami Bahri

How one diagram can improve productivity beyond your expectations

“Information, no matter how complete or speedy, is not knowledge. Knowledge has temporal spread. Knowledge comes from theory. Without theory, there is no way to use the information that comes to us on the instant.” Those are the words of management guru W. Edwards Deming in his book, The New Economics: For Industry, Government, Education.

The theory Deming invented is called Total Quality Management (TQM) — later, it evolved into six sigma. In the evolution of management knowledge, TQM evolved in the same period as the Lean Management Theory created by Toyota; and the two theories seem to be influenced by each other.

Going back to the above mentioned quote, Deming clearly wanted to seek knowledge, not just information. Unfortunately, still to this day, we practice in dentistry many beliefs that he considered as merely information, not knowledge.

For example, Deming wrote against setting numerical goals. As a statistician and a system’s thinker, he knew that a process is always capable to produce a certain amount of work, which means that it will necessarily produce a certain amount of waste. To him, setting numerical goals that fall beyond to process capability is irrelevant. What is relevant is to increase the capability of a process by improving its design. To that end, Deming thinks that the only way is to follow a theory of process improvement. In my own experience, Lean is the best theory today. However, it can become richer if we combine it with Deming’s 14 principles of management.

Here is another practice that Deming admonished. How many times have you heard a manager say that if you can’t measure it you can’t manage it? Although a statistician is supposed to put a great deal of importance on numbers, Deming preferred a theory for improvement over measurements and numerical information as he wrote: “It is wrong to suppose that if you can’t measure it you can’t manage it — a costly myth.”

What did Deming recommend?

Deming did not stop at saying what not to do. He actually gave precious advice on what to do.

In his seminal book Out of the Crisis, he wrote that quality comes first, and when you improve it, you unleash a chain reaction. “Improve quality and costs decrease because of less rework, fewer mistakes, fewer delays, snags/ better use of machine-time and materials. This leads to improved productivity, allowing you to capture the market with better quality and lower price, which in turn allows you to stay in business and provide jobs.”

In his seminal book Out of the Crisis, he wrote that quality comes first, and when you improve it, you unleash a chain reaction. “Improve quality and costs decrease because of less rework, fewer mistakes, fewer delays, snags/ better use of machine-time and materials. This leads to improved productivity, allowing you to capture the market with better quality and lower price, which in turn allows you to stay in business and provide jobs.”

The Deming Diagram

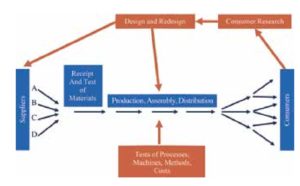

When he went to Japan to help in the rebuilding of the Japanese industrial production, Deming shared the following diagram as a basis for efficient productivity. According to him, this diagram was “… taught to hundreds of engineers, [it] commenced the transformation of Japanese industry. A new economic age had begun.” I hope that sharing it with you will commence a new economic age for dentistry.

This diagram views production as a system. Improving quality envelopes the entire production line. In our case, the production line translates into the entire chain of events that lead to the patient treatment; from the first call, to the exam and treatment planning, all the way until the mouth is totally healthy. As in lean management, Deming sees flow as the foundation of productivity;

From a flow point of view, every activity, and every job, is a part of a process.

From a flow point of view, every activity, and every job, is a part of a process.

Flow diagrams are important tools to understand and improve productivity. To draw a flow diagram of any process, we will have to divide the work into steps. The steps should not be viewed as individual entities, each running at maximum profit, but as a connected whole, forming the process.

Work comes into any step, changes state, and moves on into the next step. In other words, at every step there will be production (seen as a change of state), input changes to output, something happens to materials, papers, information or the patient that come into any step; and they go out in a different state. Then they move to the next step that in production terms, is the client of the previous step.

As such, the efficiency of every step in the process becomes totally dependent on the quality of the work passed on by the previous step. Which makes each step responsible for two important aspects of production:

- It needs to execute the work perfectly as agreed upon by the team, and pass on only good work to the next step.

- Check the quality of its own work as experienced by the next step. With this constant feedback, the previous step is responsible for continuously improving the quality of its work, aiming at better and better satisfaction of its customer, the next step. That is when the concept of continuous improvement becomes crucial

The Deming/Shewhart Cycle

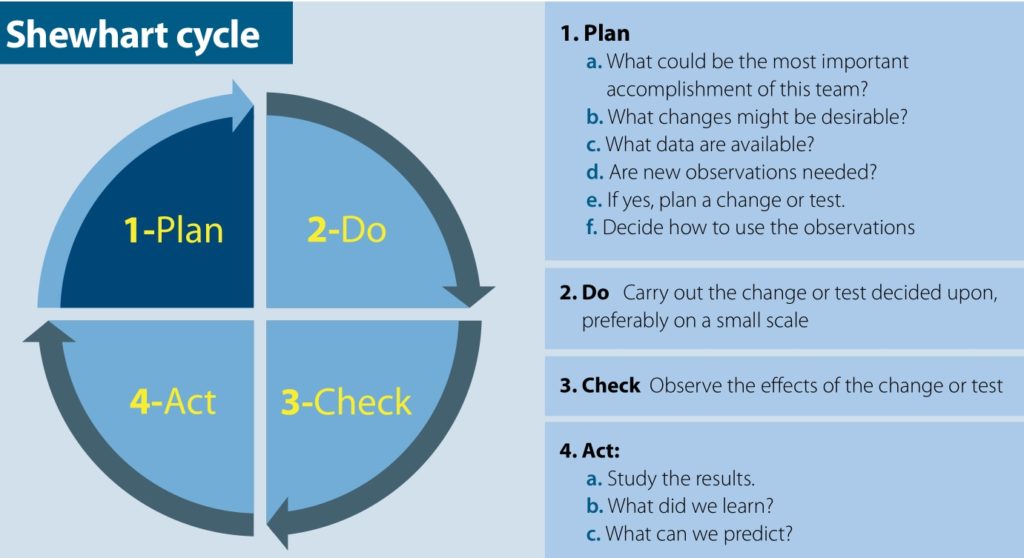

Continuous improvement is a fact of life, otherwise, we would still be living like the Stone Age. Lean management took the idea from Deming, and his teacher, Walter A. Shewhart, and systematized it. It became part of a relentless pursuit for improving every aspect of production by everyone, everywhere in the practice, at all times.

Deming presented the following diagram to guide us through the efforts of continuous improvement; it is called the PDCA (Plan, Do, Check, Act) cycle. It is called a cycle, because it was conceived to be repeated indefinitely. We can never reach perfection and because every time we find an improvement idea, it can last until the environment changes. Technology changes, dental science changes, employees come and go; change is inevitable and the PDCA cycle helps us deal with it.

In conclusion, according to Deming, we need to follow a management theory if we intend to move our practices to the next level. The latest and most advanced theory in my judgement is Lean management. I hope to see dentistry move into the new era, the era of lean dental management that allows patients, practices and everyone who deals with them, to benefit. At the same time, I find the management principles that Deming taught to be timeless and invaluable. I strongly encourage you to learn them, the resources are readily available and abundant. Finally, continuous improvement is the way to apply those theories. If you have any questions, email me at [email protected].