As a leader, bring positive energy to work with the right activities

By Dr. Sami Bahri

The second law of thermodynamics is the law of entropy; it states that systems deteriorate if left unattended.

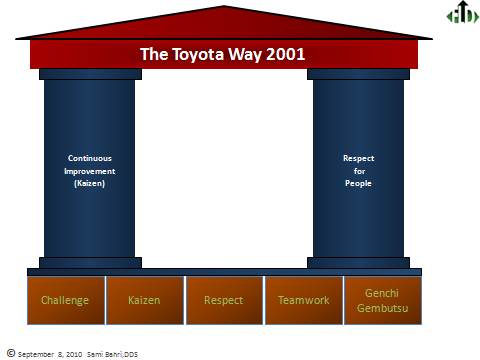

One way to prevent deterioration is to enhance processes constantly – that is the principle of “continuous improvement.” In 2001, Toyota published a document containing the drawing in Figure 1. It shows the principles of Lean Management, with “Continuous improvement” as one of its two foundational pillars.

Continuous Improvement overcomes entropy

To overcome the negative effects of entropy, we need to bring positive energy to work. That energy comes from the efforts of team members who improve every process, everywhere, everyday; it is simply called leadership.

Leaders define leadership differently to match their management philosophy. While many believe in command and control types of leadership – where managers dictate and workers execute – we believe in the following definition:

Leadership means taking initiative in your scope of work, and beyond whenever possible, to improve personal and collective knowledge and skills, in order to get the environment closer and closer to a common, ideal vision.

As you can see, we believe that leadership belongs to everyone, not only the person at the top, like the dentist or the office manager. Taking initiative in learning and improvement is essential at all levels of the practice.

Not every initiative breads improvement, though; some can lead to inferior results. To sort good initiatives from bad, we need to affirm that our activities are moving in the right direction, in line with the practice’s overarching plans.

Here is a metaphor to illustrate the point: Imagine that you are lost in the middle of a jungle. A boat is waiting in the ocean to save you, but you don’t know which direction leads to it.

Without a clear direction, you can cut trees in a circle until the ocean comes into view, or you can follow a random direction. The first option is too slow; the second uncertain. Neither guarantees that you will reach your destination in time.

Now imagine that you found a stream of water flowing nearby, which leads to the ocean. In this case, you could simply clear the trees along the water stream; now you are more likely to reach your destination in time.

The same reasoning applies to continuous improvement and waste elimination in management. The trees symbolize the waste in our processes, if you try to improve randomly, you might not see tangible results for a long time. We have practiced random improvement for 13 years with no tangible results.

The water stream represents a concept that gives you direction for your improvement initiatives. We call it “One-patient flow”; if you improve towards it you will see immediate results. After we adopted the “One-patient flow” direction, it took us only two weeks to see the waiting time go down from more than an hour, to less than five minutes. During that year, we saw dramatic productivity improvements that remain sustained to this day.

Definition of “One-patient flow”

“One-patient flow” means that the patient moves from one value-adding treatment step to the next value-adding treatment step without any delays or interruptions until all the treatment is finished.

That is not always possible, evidently! “One-patient flow” is an ideal situation that will be reached occasionally, but not all the time. It acts as a direction giver: as long as we are moving towards it, we know that we are doing the right thing; that is why it is also called a “True-North goal.”

This concept might seem unfamiliar at first, until we see that every improvement evolves naturally toward “One-piece flow” (the industrial term for “One-patient flow”.)

In “Toyota Kata: Managing people for improvement, Adaptiveness, and superior results,” author Mike Rother gives the following examples:

- Prior to the fifteenth century if you wanted a book, someone had to write it out by hand. Then Gutenberg began printing them. Eventually publishing companies were born and you could buy a book at the store, during business hours. Now you order the book online anytime, and perhaps it is even downloaded to your reading device or printer.

- At one time we sent letters by horse rider. Then came mail coaches. Following that came once-daily delivery to your doorstep. Today we communicate at any time, via telephone, e-mail, and Skype.

Remarkably, we still find plenty of organizations that argue internally about whether to accept this endless trend toward 1×1 flow — as if it were something we have the power to control. (Rother 2009-08-11)

Dental processes evolve toward “One-piece flow,” as well:

- At one time, we needed to fill out patient charts, file them, and retrieve them on the next appointment. Today, we fill out the chart and store it electronically, with virtually no wait in between the steps.

- We used to take X-rays in one location, process them in the dark room, and take them back to the operatory. Today, with digital x-rays, there is no more wait between the different steps.

- We took impressions, sent them to the lab, and waited for crowns to come back. Today, those of us who have CAD-CAM technology don’t have to wait between the steps anymore.

All of these examples show how customers and providers alike are improving towards “One-piece flow.” In our practice, we have adapted this concept to dentistry. We replace “piece” with “patient” and called it “One-patient flow.” With lean management, the pursuit of “One-patient flow” is not passive, it is systematic, vigorous, and relentless

Subhead: Understanding the structure of treatment

One way to continuous improvement is to identify and eliminate from our processes the well-published seven wastes. But after eliminating the “low hanging fruits”, it becomes more difficult to recognize waste. Fortunately, lean thinkers have created techniques to uncover it.

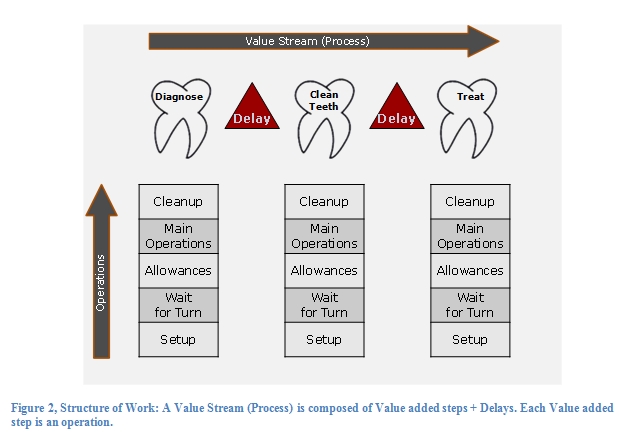

Among those techniques, “One-patient flow” offers the best chances of bringing waste to the surface. To understand this concept, however, one needs to be familiar with the structure of work as presented in figure 2. (Adopted from the work of Shigeo Shingo)

As you can see, the value-added treatment steps are placed on the horizontal line called a “Value Stream.” Each step is called an operation. All operations have the same components: Setup, wait, allowances (hygiene and personal needs), Main operations (treatment), and cleanup.

If “One-patient flow” means to move from one treatment step (represented by the drawing of a tooth) to the next with no delay, we will need to eliminate delays (the triangles in the drawing). The longest form of delay is the wait between appointments. Consequently, the main factor in improving productivity becomes reducing the number of appointments needed to complete a treatment plan. One might think of many reasons why that cannot happen all the time; but that is not important.

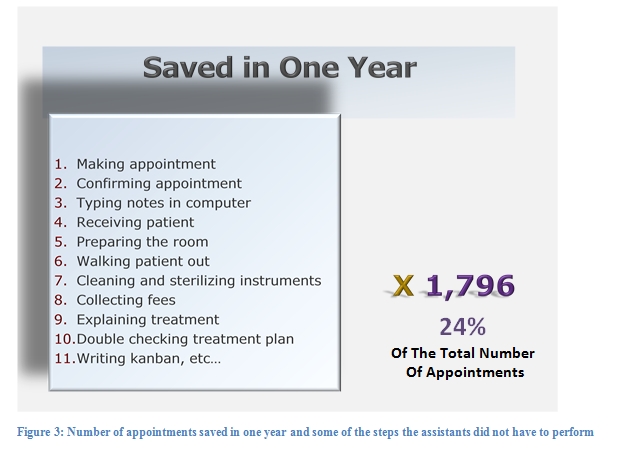

What’s important is to reduce the number of appointments whenever possible. If every dentist saves one appointment per day, you save between 200 and 250 appointments a year, with all that steps that accompany them. When we have moved to “One-patient flow” treatment in 2006, we have saved 1796 appointments, or 24 percent of the total number of appointments.

In figure 3, I have listed randomly some of the usual steps that take place in every appointment. Multiply those by the number of saved appointments, and you will get an idea on how much work we have saved for our assistants, allowing them to focus on additional procedures, without having to work harder.

In conclusion, I would like to repeat the main points:

- Continuous improvement is happening whether we like it or not. Lean management embraces this truth and takes it a step further by making it part of the management system.

- Continuous improvement evolves naturally towards “One-piece flow” in general, “One-patient flow” in healthcare and dentistry. Lean embraces it and makes it its “true north” for improvement activities.

- The most important factor to improving “One-patient flow” and productivity is to reduce the number of appointments it takes to finish a treatment plan.

Please let me know if you have any comments or questions. My email is [email protected]