By Dr. Sami Bahri

If you want to maximize productivity, reconsider how you organize work. Instead of thinking of what the workers are doing, think “what is happening to the patient’s treatment?” Is it continuous (one-patient flow), or is it stop and go, spread over several appointments?

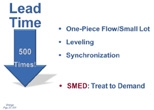

Figure 1: The only four factors you need to know in order to reduce Treatment Lead Time

Figure 1: The only four factors you need to know in order to reduce Treatment Lead Time

Make it continuous whenever possible. Then constantly shorten the time from the start of treatment until the full mouth is healthy – which is called treatment “lead time.” But beware! Any time spent between appointments counts in the lead time. If two appointments are separated by two days, the lead time would be two days. If they are separated by two weeks, the lead time would be two weeks. That makes it essential that we minimize the number of appointments instead of spreading the treatment over several shorter appointments.

To shorten the treatment “lead time” consider these four lean strategies. Every effort to increase productivity in the practice falls into one of these categories:

Leveling the schedule

Leveling the schedule is an ideal state of operations where the amount of work is equalized every hour of the day during the entire year.

To achieve leveling, we need to analyze the procedures performed during the previous year, and distribute them evenly over the projected time for the coming year. All of this should be reflected in the schedule. Making the work even every day reduces the need for resources, and utilizes fewer people, thus less money, less space and less effort.

One-patient flow

One-patient flow is an ideal state of operations in dentistry where we hope to treat everything we diagnose in the same visit. For instance, if we find that the patient needs an exam, three fillings, two crowns, and a root canal, in an ideal “one-patient flow” world, all of that is done immediately, in the same visit.

That is certainly not always possible; that is why we call it a True North goal – a goal that is not fully reachable, but gives you direction. As long as you are moving in that direction, you will know that you are doing the right thing.

As you strive to improve, you will be able to add more and more procedures to “one-patient flow.” For example, if you cannot finish a crown in the same visit because you send it to a dental lab, adding CAD/CAM technology to your practice would allow you to finish it in the same visit, adding the crown procedure to the “one-patient flow.”

In “one-patient flow,” not only is the treatment supposed to be finished in one appointment, but also all the supporting activities; the insurance claim should be filed, the notes written in the chart, the lab scripts filled, the payment collected, the next appointment scheduled, etc.

Quick room turn over and quick set up turn over

When pursuing “one-patient flow” in a given visit, we will perform a variety of procedures from a simple cleaning moving through simple and complex composite fillings for example, to veneers or crowns. The materials and instruments for those procedures need to surround the operator ergonomically, allowing to move seamlessly from one procedure to the next; and ideally, without the help of an assistant.

When pursuing “one-patient flow” in a given visit, we will perform a variety of procedures from a simple cleaning moving through simple and complex composite fillings for example, to veneers or crowns. The materials and instruments for those procedures need to surround the operator ergonomically, allowing to move seamlessly from one procedure to the next; and ideally, without the help of an assistant.

We also need to set up the rooms and turn them over between patients quickly. To that end, based on the Single Minute Exchange of Dies created (SMED) created by Shigeo Shingo, we think of setup in two terms.

- The first is called external setup: activities that can be performed even if the patient is still in the chair. An example would be moving the instruments that are no longer needed to the sterilization area. External setup is what we need to strive for. We need to clean everything we can clean and reorganize everything we can reorganize while the patient is still in the chair, so we can turn the room over as quickly as possible.

- The second term we need to be familiar with is internal setup: activities that cannot be performed unless the patient is outside the room. An example would be to change the plastic cover of the chair; this cannot be done unless the patient is out of the chair.

As we analyze the different activities belonging to the two kinds of setups, we will see that with a little analysis, some of the internal setup steps could be transformed into external setup, allowing to turn the rooms over much faster.

Synchronization

Synchronization means directing the different providers to where they are needed exactly at the time they are needed – not before or after (this is called Just-In-Time). Experience has revealed that if we utilize our resources only when they are needed, not before or after, we can save a remarkable amount of time money and efforts. Just-In-Time is the least expensive way to perform any task.

To coordinate the movement of providers in our office, we utilize a sheet of paper that we call Kanban – Japanese for signal. We are not trying to be fancy here by utilizing Japanese terminology, but because when I was studying the Toyota production system, I found that American engineers have adopted the term in their daily language. To stay true to the management environment and to avoid confusing any person trying to research the subject, we decided to use the original Japanese term, Kanban.

The importance of Kanban is that it directs the providers to their next movement. If you always know your best “next move,” you can go through your day in the most efficient manner.

But for everyone to know their best next move, someone needs to think for us. It is said for example, that President Carter relied on his staff to inform him where he should be and what he should be doing at any moment. Similarly, we have created a position (that people are starting to utilize in hospitals,) called “Patient Care Flow Manager.” The flow manager’s job is to supervise patients, not workers, and make sure that they are receiving value-added work all the time. If the assistants are busy, the flow manager starts helping the patient until someone is freed up to take over.

Another important aspect of the flow manager’s job is to constantly watch for anything that frustrates providers and constantly improve it. She corrects any conditions causing frustration, like excessive walking or missing instruments and materials from the operatories, or mistakes in the patient’s file and in insurance claim filing, etc.

Continuous improvement

In conclusion, if you want to improve productivity, it is important to know how to organize work around the patient, not the operator. In dentistry, we try to perform “one-patient flow.” In an ideal world, everything is diagnosed and treated in the same day. But, since we know that in many cases that is not possible, we utilize continuous improvement and problem-solving techniques not described in this article, to remove any obstacles preventing us from performing “one-patient flow.”

Over time, these techniques help us reduce the treatment lead time, a major factor in productivity improvement. However, before those techniques can be used, we have to prepare the field by organizing the work around the four principles mentioned in this article. This kind of organization makes problems more visible, allowing us to resolve them one by one and leading to unlimited productivity improvements.